We are a

Biomedical Contract Development

& Manufacturing Organization

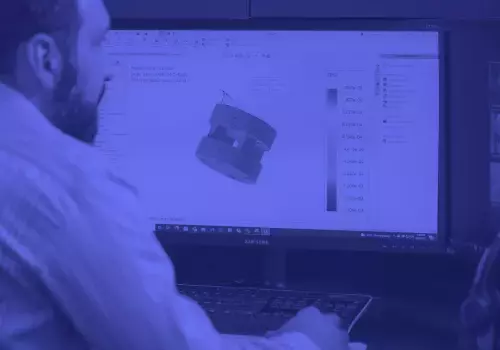

At Humanetics Biomed we pride ourselves on our technical engineering expertise in the research and development of components and sub-components for medical devices. Our team of skilled professionals has extensive experience in a wide range of specialized fields, including strain gage sensors, material processing, laser micromachining, optical fiber processing, and fiber optics.

Using our state-of-the-art facilities and advanced technologies, we are able to automate and scale production for our customers, ensuring that they receive high-quality components and sub-components that meet their exact specifications. Whether you need assistance with prototyping, design, development, or production, we have the knowledge and expertise necessary to help you achieve your goals and bring your innovative medical devices to market.

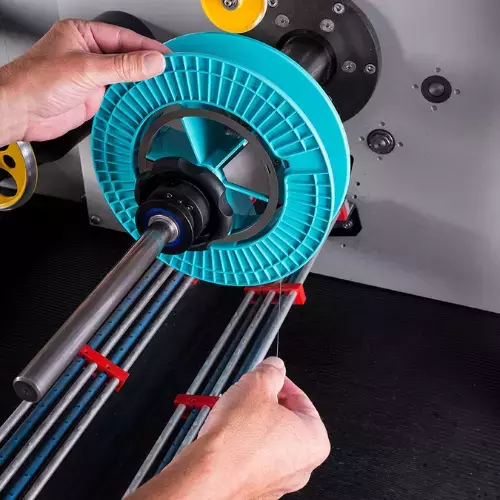

Specialized Fibers

Global leader in specialty optical fiber solutions that enable precise sensing and laser power delivery in the world’s most demanding environments.

Specialist fiber optics and fiber optic consultancy with flexible order volumes to support both R&D and scaled production processes.

Custom Sensors

Unrivaled innovation for load cells, torque sensors and custom strain gage assemblies for medical, aerospace and many other industries.

Highly reliable design and development of custom strain gage assemblies for use in regulated and critical environments.

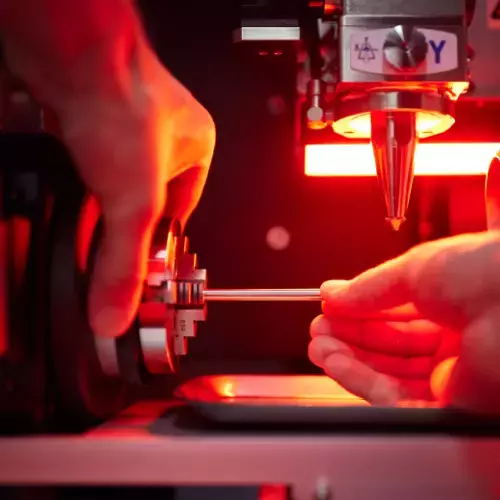

Laser Engineering

World leading laser micromachining and optical-fiber processing services and tools meeting precision manufacturing challenges worldwide.

Outsourced manufacturing, micro machining and fiber processing; machine automation to address manufacturing needs on any material.

Humanetics Biomed operates in six manufacturing facilities across the USA, Europe (UK),

and Asia (Sri Lanka and China) with a workforce of 300 employees.

For over 50 years, we have been serving the Biomed sector, and our existing clientele comprises 60% of the largest medical companies as well as numerous smaller niche customers.

The areas in which we work

Diagnostics

| Primary | Secondary | Application |

|---|---|---|

Imaging | X-Ray, CT, MRI, Ultrasound | High Speed Grooving, Connector Ribbon Strip/Cleave, OCT, Fab-Per, Contrast Media Injection Pressure Monitoring |

In-Vitro | Blood, tissue testing, DNA | Drilled Polymers, Micro-Fluidics, Spectroscopy |

Implantables | Blood Glucose | Cut tubes, parylene removal, micro needle machining, wire ablation |

Supplies & Equipment | Bandages, Stickers, Tools | Black Marking, Surface Treatments |

Telemedicine | Sensors | Bleed-out detection |

mHealth | Sensors |

Therapeutics

| Primary | Secondary | Application |

|---|---|---|

Implantables | Insulin Pumps | Hypotubes, Stents, Eluting Stents manufacture |

Implantables | Pacemakers | Welded Cases, Small Component machining |

Implantables | Hearing Aids | Welded Cases, Small Component machining |

Implantables | Implantable Defibs | Welded Cases, Small Component machining |

Implantables | Dental | Hard Material, Small Component machining |

Implantables | Ocular | Machining of lenses for surgical implant |

| Primary | Secondary | Application |

|---|---|---|

Acute Surgical | Neurovascular | Stents & Hypotubes |

Acute Surgical | Peripheral | Stents & Hypotubes |

Acute Surgical | General Surgery | Special closure tubes |

Acute Surgical | Dental | Treatment delivery & tips |

Acute Surgical | Illumination | Treatment delivery & tips |

Acute Surgical | Optical Based Surgery | High power delivery of optical energy |

Acute Surgical | Bone Impants | Wireless sensors (HITEC) |

Acute Surgical | Bleed / wound treatment | Cutting of material under defined paramters, Force sensing surgical stapler |

Acute Surgical | Needle / Catheter | Formed, drilled and shaped needles/catheters |

Acute Surgical | Robotic Surgery | Haptic feedback sensor |

Acute Surgical | Operating Room | Patient weighing and positioning |

| Primary | Secondary | Application |

|---|---|---|

Chronic Treatment | Infusion Pumps | Pressure Sensor |

Chronic Treatment | Chemo Pumps | Pressure Sensor |

Chronic Treatment | Dialysis | Bleed out detection |

Chronic Treatment | Masks | Hydrophobic patterning |

Chronic Treatment | Dosage Cups | Hydrophobic patterning |

| Primary | Secondary | Application |

|---|---|---|

Rehabilitation | Mobility | Exercice rehab bike, Gait trainer machine |

Pharmaceutical Packaging

| Primary | Secondary | Application |

|---|---|---|

CCIT - Glass | Tubes & Phials | Controlled damage to item by laser |

CCIT - Glass | Other | Controlled damage to item by laser |

CCIT - Polymer | Tubes & Phials | Controlled damage to item by laser |

CCIT - Polymer | Flat Containers | Controlled damage to item by laser |

Humanetics Biomed Services

Work with customers’ engineers to design custom solutions

Enable fast turn around times and speed to market

Help customers innovate and create new cutting-edge products

Technical consultancy

50 laser workstations & labs

Access to world class engineers

Selection and testing of material components

Process design and quality testing

Assembly automation and certification

3 fiber optic draw towers

5 centers of excellence

Transition from pre-production to full scale production

Provide space and small-scale skilled workforce in assembly techniques

Global manufacturing network for location benefits

200,000+ medical sensors & 1,000,000+ lasered components

6 locations, 140,000 sq. ft manufacturing facilities

ISO Certified

Develop automated manufacturing processes

Automated picking and packing into cartridges

Modular design and AI visual quality control checks

Scalable production volumes from R&D to mass manufacturing

20-30% OpEx cost reduction

Discover our Biomedical capabilities

HITEC is a custom sensor design and outsourced manufacturing supplier with manufacturing facilities in Boston, MA and Kadawatha, Sri Lanka and a sales office in the UK.

HITEC’s USP is its deep and trusted technical knowledge of designing custom sensor solutions in critical applications that cannot, and do not fail. Through engineering partnerships, HITEC enables sensors to be built-in, and then production scaled.

HITEC is continually developing process automation, using OpTek machines and capabilities, we will extend and replicate this for our customers.

Currently is certified for Aerospace and is pursuing medical device certification for ISO 13485.

Core Biomedical Capabilities

Liquid flow monitoring Occlusion and infusion pump sensors are used to measure liquid flow, drug treatment, blood pressure. |

Haptic feedback sensors Six axis sensors are used to give surgeons precise feedback while performing remote surgery. |

Rehabilitation & Orthopedics Machines and embedded devices are used to measure force and exertion. This data helps doctors manage patient recovery and rehabilitation in real-time. |

Custom Force Sensors Many surgical tools like disposable staplers, and drills used in bone surgery, need sensors to monitor forces acting upon the tool. |

OPTEK provides outsourced manufacturing services for fiber processing, lensing and micromachining sub-components across a range of niche applications, with a core manufacturing base in Oxford, UK; and additional facilities in Greenville, SC; Boston, MA; and DongGuan, China.

OpTek also creates customized laser machines used by customers at their own facilities to perform tasks like black-marking. Previous customers that have bought machines have expressed an interest to change to an outsourced manufacturing model.

OpTek’s USP is designing automation machines to manage laser wavelengths that can process any material at accuracy of between 1-300microns, at repeatable scale.

Core Biomedical Capabilities

Tube & Wire Processing Cutting and setting nitinol, magnesium, stainless steel, polymers for stents and other medical components. |

Laser Fiber Processing Stripping, Cleaving, Cutting and Lensing of optical fibers for therapeutic and diagnostic applications such as dentistry and dialysis bleed detection. Fiber Bragg Gratings provide precision sensing along the fiber. |

Laser Micro Machining R+D Dev elopement and sub-contract drilling, milling and surface treatment of challenging materials such as organics, foils and laminated polymers using automated and manual laser processes. |

Black-Marking Marking of medical and pharmaceutical consumables and equipment with regulatory and customer information. Marking of challenging shapes and materials with inbuild machine learning quality assurance. |

Micro-drilling Creation of precision, high aspect ratio holes and slots in catheters, needles, IV and aerosol delivery systems. Supports creation of known-bad defects in container integrity testing. |

Fibercore is the global leader in specialty optical fiber solutions that enable precise sensing and control in the world’s most demanding and harsh environments and is based in Southampton, UK

Fibercore’s range of specialty fiber include Single Mode, Multi Mode, Doped, Fiber Bragg Gratings, Polarization Maintaining Fiber and much more to meet demanding and unique customer applications.

Fibercore’s robust polyimide coatings are proven to be compatible with biomedical sterilization processes.

Fibercore offers excellent process control and full test report provided with every spool of fiber

Fibercore ensures the best optical fiber is designed into our customers application to optimum performance.

Core Biomedical Capabilities

Large core fiber for laser surgery and spectroscopy |

Fiber Bragg Grating (FBG) sensors |

SM and PM polyimide coated fiber for FBG based sensors |

Reduced cladding, bend insensitive fiber for streamlined endoscopes |

Twin Hole Fiber for Pressure Sensing FBG inscribed Twin Hole fiber can be used to monitor pressure in vivo. Specific applications include: monitoring pressure within blood vessels and heart chambers during Minimally Invasive Surgery (MIS). |

Discover our work in action

The implementation of force sensors in infusion pumps helps regulate fluid delivery and dosage to a patient and can also detect possible occlusions and blockages via pressure changes.

Advanced spinal screws that incorporate HITEC’s torque and strain sensors can ensure the correct size and position of the screws and rods; and help to reduce the risk of post-surgery complications.

Strain gauge technology doesn’t come in a one size fits all scenario. The solutions are as diverse and individual as are the applications for which they are specified and developed.

The function of many drug-delivery, therapeutic, and medical device systems often relies on a change in force. Learn about how this change can be initiated by either the patient or can be automatically changed by the device itself.

In this on-demand webinar, we will explore how specialty optical fibers can be applied to a number of applications within the Biomedical field, such as Haptic Feedback, Chemical Sensing, Endoscopy and many more.

We are improving healthcare diagnosis, treatment, and outcomes through innovative design, precise manufacturing, and scalable production.