PUtting Safety to the test

Humanetics develops state-of-the-art test equipment that crash test engineers use to ensure the ATDs are always in perfect working condition, properly calibrated and certified and to ensure that tests produce data with efficiency, accuracy and repeatability.

Our suite of equipment also features critical tools used by automotive OEMs and suppliers as well as government and independent testing facilities to evaluate advanced driver-assistance systems (ADAS) and autonomous vehicles.

You could be forgiven for mistaking our laboratory equipment for a chamber of horrors, we prefer to think of it as a fitness laboratory for elite athletes training to go into public service.

Chris O’Connor, President & CEO, Humanetics

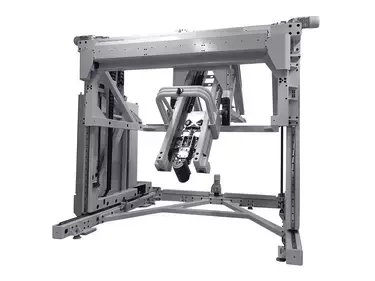

Humanetics offers a complete portfolio of test fixtures for a crash test laboratory to certify the entire set of ATDs that Humanetics manufactures. This includes tools that enable full body testing as well as all necessary component-level testing.

Our fixtures are designed to test individual components of the dummy. For example, the Neck Pendulum is used to calibrate the mechanical properties of the neck and lumbar assemblies. Specifically, it tests the velocity at impact, pendulum acceleration, total rotation of the head/ neck system, moment about the occipital condyle and force. The Thorax Impact stand is a huge piece of equipment and is used to test the thorax compression of frontal and side ATDs.

This portfolio of fixtures meets the requirements of all American and European regulations as well as other non-regulated SAE recommended certification practices. Where applicable, Humanetics provides certification certificates of probes, pendulums and other hardware that meet Code of Federal Regulations requirements and can provide re-certification services as needed.