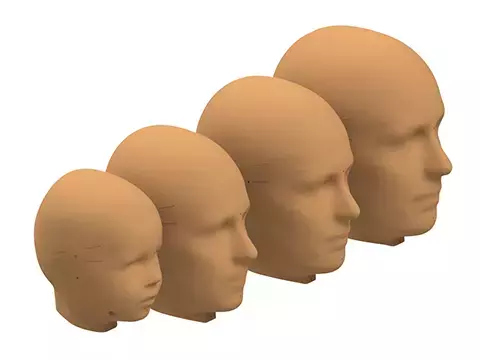

Our specialized headforms enable engineers to design safety features that protect the most vital part of the body. They are used extensively in interior vehicle design to evaluate occupant safety as well as exterior design to help minimize pedestrian injuries. Defense and aerospace engineers also use them to test helmets and other head protection equipment. Our headforms are instrumented with special plates and sensors to provide data on how directional impacts and forces affect different parts of the head.

Our eyeglass dummy headforms are specified in ASTM standards for testing of protective eyewear. They allow the tester to ensure an appropriate level of protection for sports and industrial eyewear. These tests involve launching projectiles at the headform.

The deformable face headform was developed in response to SAE papers and is used to tailor the impact response of the head when the nose area hits the steering wheel. The deformation leaves a record of the contact, allowing vehicle engineers to test steering wheel designs that minimize facial injury and head acceleration caused by contact.

Free motion headforms are launched by robot arms to impact various interior surfaces in the car in a controlled manner. These controlled impacts would be impossible to perform with the head mounted on a dummy. Through these tests, vehicle designers can tailor interior vehicle surfaces to help prevent or reduce head injury.

The ejection mitigation headform, 18KG head, is used to test the ability of side curtain airbags to restrain the vehicle occupant’s head within the vehicle during a rollover accident.

Spherical headforms are launched at the windshield in American, European, and Asian vehicle tests to simulate a pedestrian head strike. Compared to a full pedestrian dummy, these headforms enable more precise control of impact locations, providing data that enables improved pedestrian protection in windshield designs.