Multidimension Test System

The Multidimension (MD) Test System stand-alone solution is based on the drop/compression module of the PDC Test System. Using the available extensions, MDT+, the MD is able to carry out force, torque and multi-dimensional displacement sensor calibrations on both test systems in addition to the drop and compression tests. If a test laboratory is equipped with both, a PDC and an MD test system, even faster throughput times can be achieved with a well thought-out distribution of the equipment.

Specifications

Key Features

The system can conduct tests with forces of up to 1 kN in the X and Y directions (horizontal). Forces up to 25 kN are intended in the Z direction (vertical) and can be implemented at the customer's request. With a high positioning accuracy of 0.01 mm, the user has many options for crash test dummy component testing and sensor calibration.

MDT+

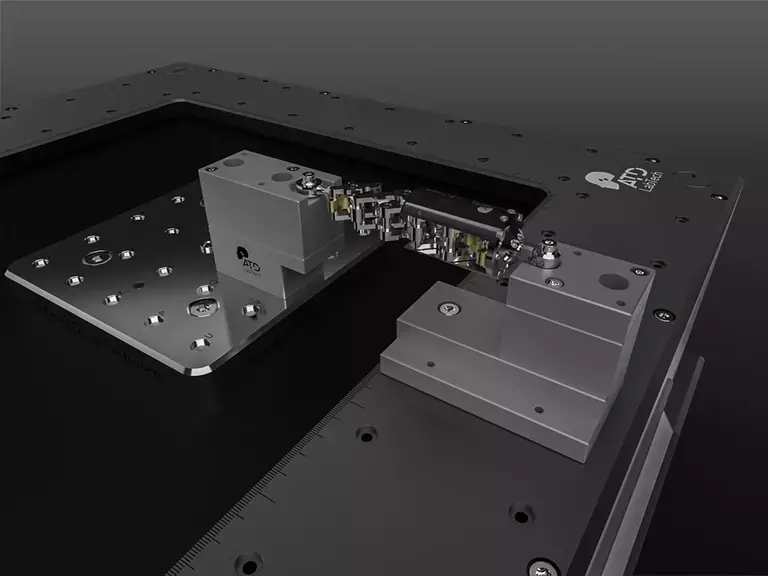

The compact MDT+ expands the two additional dimensions for the MD and PDC test system: The vertical Z-axis, represented by precise linear modules, is supplemented with the X and Y axes, the movable table part of the MDT+.

To make the area usable again for drop tests, the unit can be stowed in the rear area of the test bench.

An integrated glass scale-based measuring system is available as an upgrade. The glass scales of the axes can be removed for annual calibration.